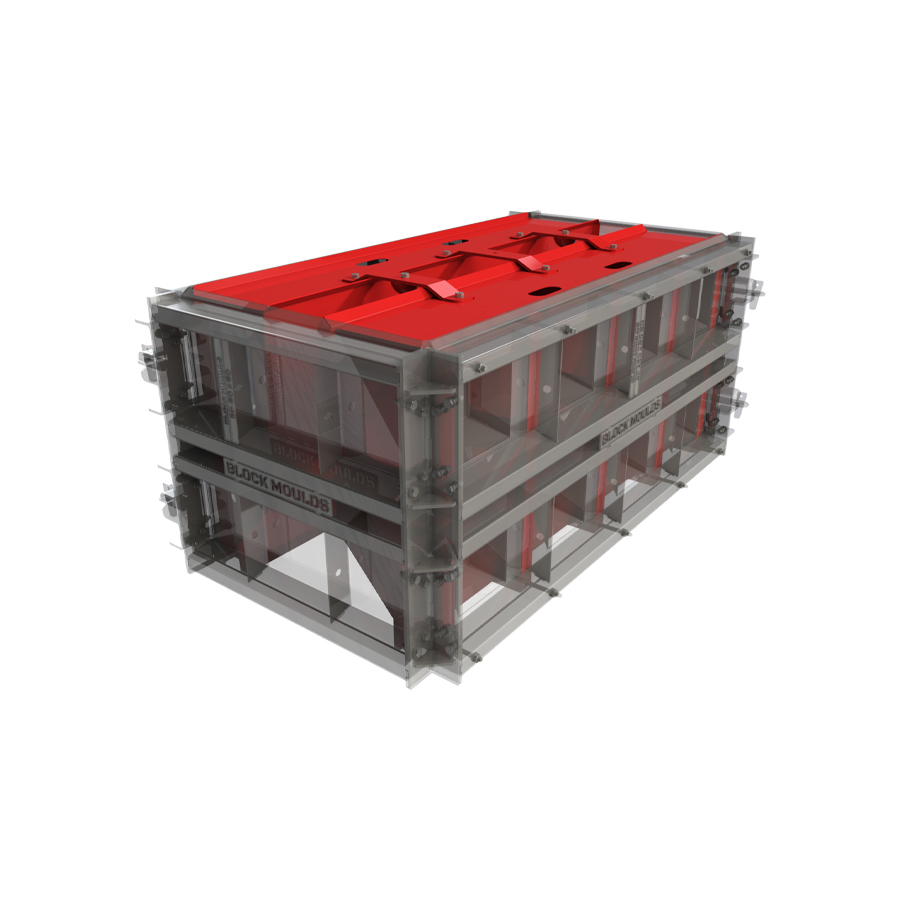

Jersey Road Barrier insert

The unique patented insert for producing concrete jersey barriers. No need for expensive separate moulds. To be used together with our basic mould to produce a variety of concrete blocks.

Jersey barriers reduce the risk of accidents and are used to manage traffic and safety on roads and at construction sites, large crowd events and festivals. The precast concrete barriers offer maximum durability and require minimum maintenance.

These road safety barrier blocks provide a fast and effective solution for anti-vehicle perimeter protection and restricted access management. Especially useful to protect industrial estates, construction sites, unoccupied buildings and to delineate pedestrian routes, traffic and storage areas.

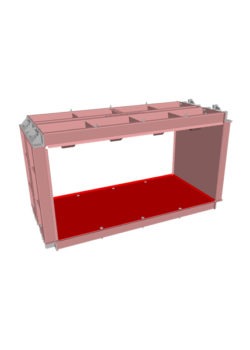

Easy handling of barriers

A concrete block with forklift slots can be produced by using the forklift slot inserts. The forklift slots allow the precast Jersey barrier to be moved with minimal manpower and time. Ideal when barriers are temporary used to direct traffic during road construction and road closures and for crowd control management at festivals.

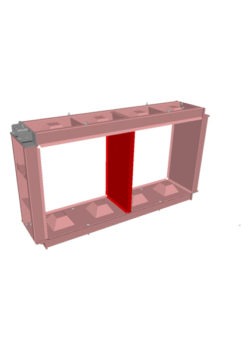

Smaller lengths of barrier blocks

Do you need to produce smaller blocks jersey barriers suitable for your project? Use the Jersey Divider to vertically shorten the mould.

Tapered end barrier blocks

Slope end Jersey Blocks are used when you need a barrier with a smooth transition from high to low. The smooth transition can be created by installing the slope insert into the mould.

Easy Filler

We supply easy filler hoppers to guide the concrete through the narrow opening during pouring.

Fastening Accessories

Make sure the mould is on a flat surface and use our casting table with adjustable feet.

To avoid that the mould will be pressed up from the ground when pouring concrete too fast (risk of floating), we strongly recommend to use two lashing straps to secure the mould to the casting table.

Or simply move the lashing straps under the base plate (steel plate or plywood panel) if a casting table is not used, and secure the Jersey barrier mould to the ground on this way. Lashing straps can be easily hooked into the holes of the stiffener plates on the sides of the mould.

Lifting and Transport

A mechanical lifting clamp is available for lifting and transporting the concrete Jersey barrier blocks. A transport system with head anchors, lifting clutches and lifting yoke for a forklift is also available for this purpose.

Additional

| Dimensions | 160 × 80 × 80 cm |

|---|---|

| Block form | Jersey Barrier (JB) |

| Size | 160 x 80 x 80 |